600%.

That’s how much more it costs to ship a standard 40-foot container from Asia to North America.

Ian Leslie is holding his breath to see how merchants react to that.

“Are they able to swallow that? Do they want to try to recoup some of that cost by not offering deep discounts in terms of Black Friday, Cyber Monday sales tactics? Are they even going to have product to ship?” asks the Senior Director of Retail Advocacy at one-click checkout solution Bolt.

Ian talks to hundreds of merchants each year, learning their stories and making sure Bolt’s product is serving their needs. Before joining Bolt, he was on the merchant side himself, doing marketing for a D2C furniture company. He knows his way around a supply chain, and this year has him stumped—though he’s excited to keep seeing the ways retailers are getting creative as they respond to forces outside of their control.

We sat down with him to hear more about what some of those responses are, as well as how changing consumer expectations will make a lasting impact on the industry.

Understanding the state of supply chains

===========================================

Most consumers don’t know much about supply chains, says the trade publication covering them —and The Atlantic —, even though they care a lot about the outputs of them (read: the costs of goods, the shipping options available, and the environmental impact of different products).

In a full-disclosure moment, I have to admit that I fall—or fell, until starting work on this piece—into that “most consumers” bucket.

But let my crash course help you zoom through yours. There are three major steps in most supply chains: producing goods, shipping goods, and last-mile logistics of goods.

(Business schools will tell you there are a lot more moving parts involved, from sourcing raw material to planning demand to managing inventory. To simplify, we can put each of those under one of our umbrella topics: producing, shopping, last-mile logistics.)

Right now, there are problems every step of the way:

1. Producing goods

Raw material costs have risen thanks to growing inflation, higher energy costs, higher demand for electronics, and continued shortages (caused by both COVID-related production shutdowns as well as extreme weather).

Coal, metal, and other commodities in China are at a 13-year high, reports Reuters . It costs more to make textiles , cars , prepackaged food , houses , phones and PCs and anything else that needs lithium —even German sweets .

2. Shipping goods

Remember that 600% increase in the cost of shipping containers from the beginning of this article? Two main forces are driving that increase. First, as CNN explains , there’s a physical shortage of containers.

Shipping lines shut down when the pandemic hit and canceled sailings back to China, leaving empty boxes stranded in places like Europe and the United States.

Then there’s also a spike in demand for goods, also thanks to the pandemic.

Consumers are clamoring for goods like furniture, electronics, and clothing, much of which is produced in Asia, and with limited container supply, logistics companies can charge much more for their space.

3. Last-mile logistics / delivery of goods

Even if you could get the raw materials to make your products offshore, and pay the shipping costs to bring them onshore, you’d still have to deal with figuring out how to get them into your customers’ hands.

Fedex, the USPS, and UPS are all increasing their shipping costs and their estimated delivery times, reports The Wall Street Journal , to better deal with higher demand and their own supply chain issues (from higher fuel costs to a labor shortage).

“People who have really invested heavily in their last mile have seen the benefit,” says Ian, who says he’s seen brands successfully use shuttered retail spaces as distribution or local pickup centers for buy online, pick up in store options.

Choices facing retailers

===========================

If you’re a retailer, you have two main choices for dealing with your broken supply chain: fixing it or accepting it.

Web Smith, founder of media and eCommerce publisher and consultancy 2PM , notes that not everyone selling product online will be able to get into the nitty-gritty of their supply chain.

“There are a lot of marketing companies, and very few digitally native brands,” he explains. “If you are an eCommerce company that actually understands your products, it’s not that much of a quantum leap to begin figuring out how to get product over.”

He references Lori Coulter, co-founder and CEO at SUMMERSALT: “That woman knows every single thing about every piece of goods leaving the factory.”

If you have that level of understanding over your supply chain, Web says you might have success switching to air freight, buying a container, or partnering with another company who manufactures in the same area to go in on a container together.

But if you’re in bucket number two—if you’ve accepted that, as Ian says, “There’s really nothing you can do to address your supply chain at the moment”—it’s time to look for creative ways to meet customer demand.

Writing off this entire holiday season isn’t going to help you make it through the next few months. Same goes for the next few years, as pandemic- and climate change-related forces keep changing how the world demands, produces, and sells goods.

“You need to ask what you’re going to do that’s creative and tactical to try and continue to bring in cash revenue,” says Ian.

6 creative ways to deal with supply chain issues

===================================================

1. Stock third-party products

Web, who used to work for the athletic gear company Rogue, mentions their approach to stocking product—which includes goods made by brands like Nike, Adidas, and Reebok along with their own branded goods—as a potential lifeline for eComm brands.

“You can stock similar goods that are appreciated by your customer base that are available,” he says. “The risk is whether you’ll be able to generate demand for those products, and whether you can compete in paid advertising around those products.”

2. Embrace gift cards

What happens when a customer is browsing your site and sees that a product is out of stock? Maybe you get their contact info so you can reach out when it’s back. But what if you could secure the sale now?

That’s the idea behind Govalo , a Shopify app that streamlines giftcarding on the eCommerce platform.

This photo comes from this tweet about Govalo’s launch this week—and shows exactly how the gifting tool integrates into product pages.

Giving customers the option to purchase gift cards allows them to still give a coveted holiday gift even in the face of supply chain nightmares. Save Christmas and your bottom line? What’s not to love?

“Gift cards are like a zero-interest loan,” says Ian. “If more merchants can push gift cards, that’s really a good play.”

3. Explore delayed fulfillment and shipping

Delivery by December 24: expensive. Delivery sometime in Q1 of 2022: enjoy 25% off!

Ian hasn’t seen those options pop up yet, but he expects he will soon. “Brands offering increasingly higher discounts based on delayed shipping options would be really cool,” he says. “There’s a whole slew of deferred revenue issues in terms of how you’re managing your finances, but I definitely think it’s going to be out there.”

Web agrees: “You can incentive customers to spend by telling them they pay a little bit less if we can deliver really, really late.”

It may not work with people who are shopping for others, but for anyone buying their own gifts this holiday season, offering discounts can help smooth out the kinks in a backed-up supply chain.

4. Offer additional value for already-purchased products

We already know that customer lifetime value is the metric for eComm retailers to chase. It’s more lucrative—and meaningful—to have a long-term relationship with customers than it is to be constantly sprinting to bring new ones in the door.

So how are you keeping your long-term customers happy this holiday season? Especially if they have to deal with product and shipping delays they haven’t experienced before?

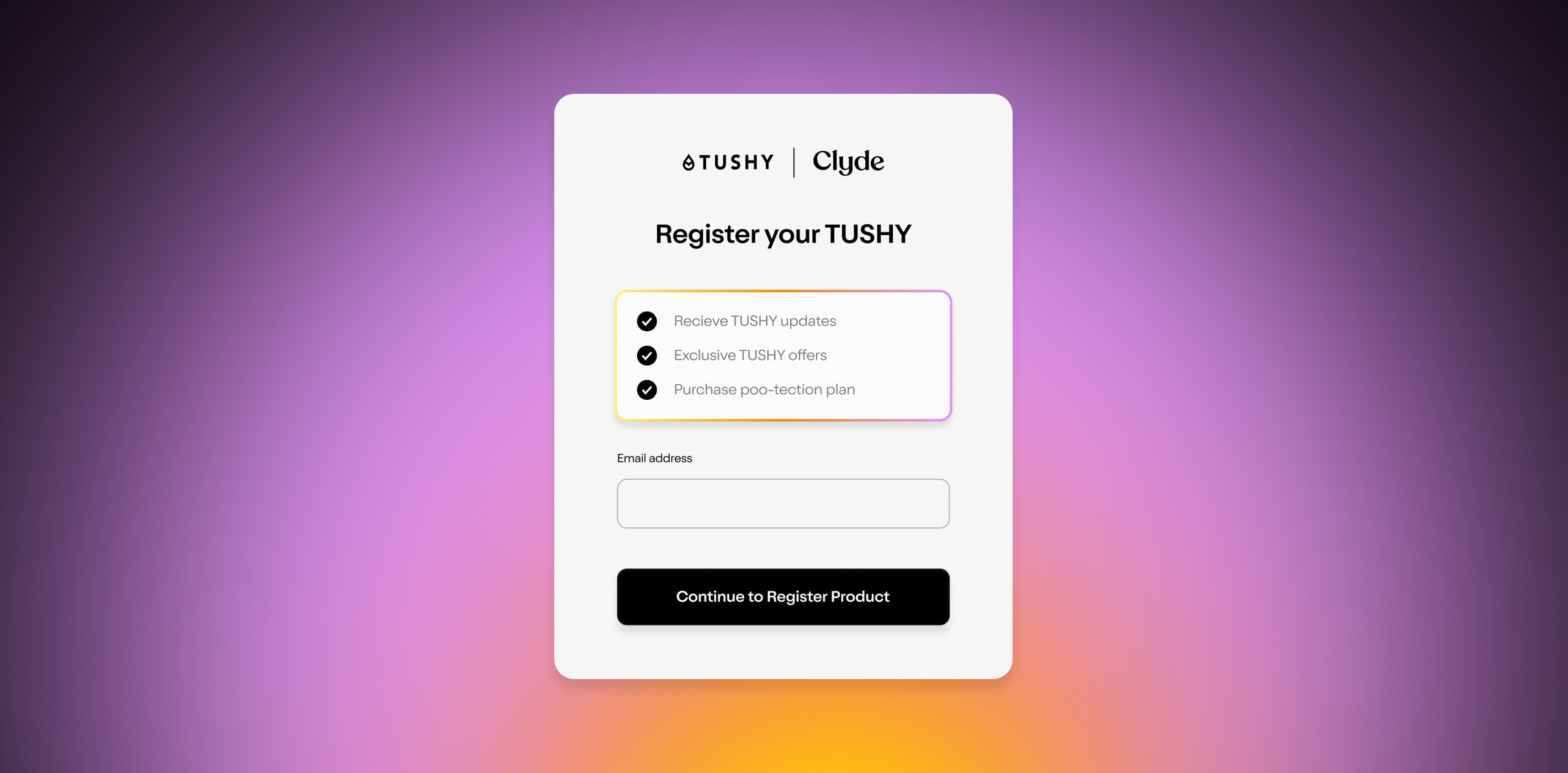

You can add additional value with product protection plans , for one. Clyde’s plans come with repair options so that your customers don’t have to wait for new replacements that may take months circumnavigating the global in the current supply chain mess. They can now get those products, covered under a warranty plan, repaired by reliable professionals.

5. Rethink how you communicate with customers

Despite the supply chain articles that keep popping up in mainstream publications, you’ll still run into consumers who have no idea what’s going on and why it’s taking so long to get the new gaming system their kid expects to see on Christmas.

It’s on you to gently educate them on what’s going on.

“Good brands have to be more forthright and proactive in letting the customers know to expect delays—and in having great customer service to deal with them,” says Ian.

Along those lines, he expects to see changes to customer-facing copy (like websites with banners explaining supply chain issues) as well as an overhaul of how customer success is set up.

“Customer service is not just the phone anymore. It’s happening across social media. We call shopping in your DMs "conversational commerce," and it’s the same thing as conversational customer service,” says Ian. “Whether it’s via chat, Instagram, Twitter DMs, or Facebook Messager, what was in the past reserved for a social media manager is going to be more customer-service facing.”

6. Double down on brand equity with digital products like NFTs

Some context on Web’s tweet:

Basketball player Jimmy Butler started selling coffee for $20/cup while playing in the NBA bubble. This October, he launched the first product line from his company Bigface—including a $500 NFT box that comes with four coffee varieties and “Bigface non-fungible artwork.”

“It’s a way of generating energy around your product while your physical goods may not be as available as you’d like them to be over the next five months,” says Web, who points to the success of luxury brands like Balenciaga creating NFTs that sell for millions.

“Shopify is seeing that smaller brands can do the same thing as long as they have the right level of brand equity,” says Web, who still expects NFT-linked products to be more niche buys and less holiday gifts unless you’re shopping for a Web3.0 super fan.

“The anticipation of a good and the popularity of the brand itself increases as a factor of the community pushing around it,” he says. “If the person has no idea what it is, you’re gifting something invisible. If you understand the economics and the potential value, that you’re getting to hold a link to a piece of digital art, there’s lots of potential.”

Looking to the future

========================

Supply chain issues aren’t magically going to turn around on January 1, 2022.

In fact, they might get even worse before they get better, with factories shutting down for Chinese New Year in February and potential future waves of COVID-19 disrupting production again.

What’s a brand to do? Seriously consider moving back onshore, says Ian.

“I’m hearing more and more people looking to bring their supply chain back onshore. If they’re going to pay the extra $30,000 [for shipping] and still experience delays, why not be able to tout that [their products are] made in America?” he explains. The calculus is tricky: it may take a minimum of 20 weeks to get an offshore container onto an American dock, with a 30k price tag, but is that still cheaper than making goods with more-expensive raw materials and labor in the States?

I asked Ian, in case he had a crystal ball he had yet to share with me, but no luck. “In terms of what is more efficient, and on what timeline, I have no idea,” he says. “If I did, I’d be a millionaire. I don’t know what’s going to solve itself first.”

Until then, he’ll be buckled in for the ride alongside the rest of us: “This will be the craziest holiday shopping season we’ve ever seen.”

SIGN UP FOR OUR NEWSLETTER